Hydraulic hose assemblies are essential components for fluid transmission in various industrial processes. Whether transferring water, chemicals, or abrasive materials, these assemblies are designed to provide flexibility, durability, and compatibility with a broad range of substances. In gem processing, hydraulic hoses play a crucial role in ensuring smooth operation, reliable fluid transfer, and minimal downtime. DHL, a leading manufacturer of industrial-grade hose assemblies, delivers solutions known for their reliability and high performance, even under the most challenging conditions.

At DHL, we use only the finest hoses and fittings to ensure compatibility with a wide range of fluids and pressures. This guarantees the longevity and efficiency of your systems.

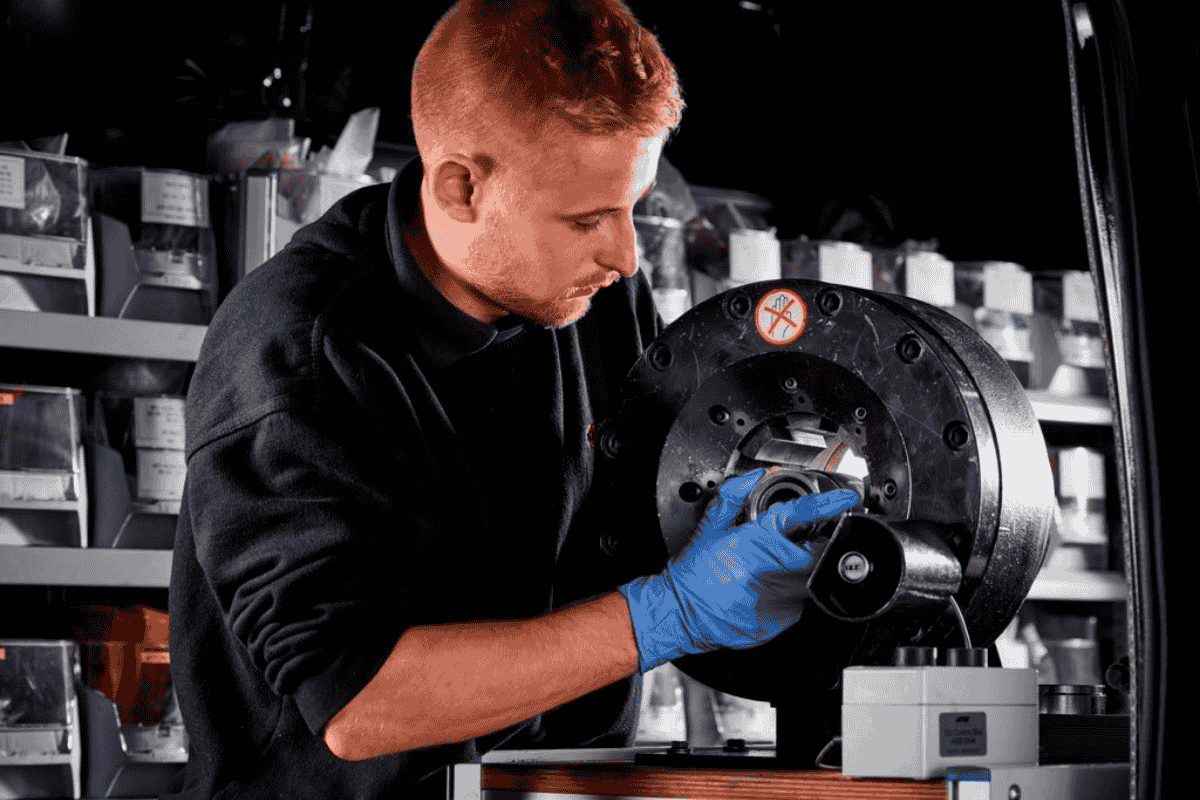

Each hose is meticulously assembled by our experienced technicians, following strict quality control standards to deliver optimal performance.

We understand that every application is unique. DHL offers a variety of hose types, lengths, and fittings to meet specific customer requirements.

Our hose assemblies are designed for resilience, resistant to wear, tear, and corrosion, ensuring they stand up to demanding industrial conditions.

DHL hose assemblies are engineered for exceptional flow rates and minimal pressure loss, enhancing the overall efficiency of your systems.

Our low-friction hoses reduce pressure loss, ensuring superior flow and better overall system performance.

The durability of our assemblies means fewer replacements and lower maintenance costs over time.

With leak-proof connections and high-pressure capabilities, our hose assemblies contribute to a safer work environment.

Our commitment to quality ensures that your systems will operate flawlessly, reducing the risk of unexpected failures and accidents.

Hydraulic hose assemblies are commonly used in industries requiring the transfer of high-pressure hydraulic fluids, such as mining, construction, agriculture, and marine operations. They consist of a flexible hose, often reinforced with materials such as wire or spiral braiding, and fitted with secure, leak-proof end fittings.

Applications Include:

These assemblies are tailored to meet the pressure, temperature, and chemical compatibility requirements of various industries.

DHL provides a wide range of hose fittings and flange options, including:

These fittings are designed to ensure leak-proof connections and compatibility with the specific requirements of your system.

We understand that not all applications are the same, so we offer customized hose assemblies and fittings tailored to your specific needs. Whether you require specialized lengths, pressure ratings, or materials, our team is equipped to deliver bespoke solutions.

DHL offers expert technical guidance, helping you select the right hose assemblies for your needs and assisting with the installation process. Our long-standing relationships with top hose manufacturers such as Gates and Parker ensure you receive the highest quality products that meet SAE standards.

A hydraulic hose is a flexible, high-pressure tube designed to carry hydraulic fluid in a hydraulic system. Hydraulic systems use pressurized fluid to transfer power and perform work, and the hose is essential in connecting various components, such as pumps, actuators, and valves. It is typically made of durable materials like thermoplastic or synthetic rubber to withstand high pressure and harsh operating conditions.

Hydraulic hoses are primarily used to allow the flow of hydraulic fluid between different components in a hydraulic system.

For preventive maintenance, the hydraulic hose should be replaced every year or two, depending on how the machine is used. However, regular inspection is required to prevent failure.

When choosing a hydraulic hose, hydraulic hose sizes like length and diameter should be given careful consideration. Temperature and pressure range, hydraulic hose material, the fitting requirement should also be considered.

Hydraulic Hose Fitting

Hydraulic fitting on the market varies in different regions, and each type has its history of usage and origin. How can we choose the right one from thousands of hydraulic fittings?

We can use five fundamental dimensions to define them: Thread type, Connect Type, Bending angle, Tail type and Seal Type.

Just like the fitting diagram shown below, you can efficiently choose the right one and get PART No. to make an order.

The dimension available:

Tail Type: swaged, interlock, socketless, reusable;

Thread Type: metric, JIC, Bspt, Bspp, Npsm, ORFS, SAE, NPT, JIS, MT.

Connection Type: Male, Female, Flange, Standpipe, Banjo, StapleLock.

Bending Angle: 90°, 45°, Straight.

Crimping and Installation:

Fittings are typically crimped onto the hydraulic hose using specialized tools. This process ensures a strong and durable bond between the hose and the fitting. The crimping process is important to maintain the pressure rating and leak-free performance of the system.

Hydraulic hose fittings come in various configurations and sizes to meet the specific needs of different systems. Understanding the thread type and compatibility is crucial when selecting the correct fitting for a hydraulic application.