We design and manufacture hydraulic cylinders, power units, and custom hydraulic systems tailored to your specific needs. Our commitment is to deliver top-quality products at competitive prices that consistently meet or exceed our customers’ expectations.

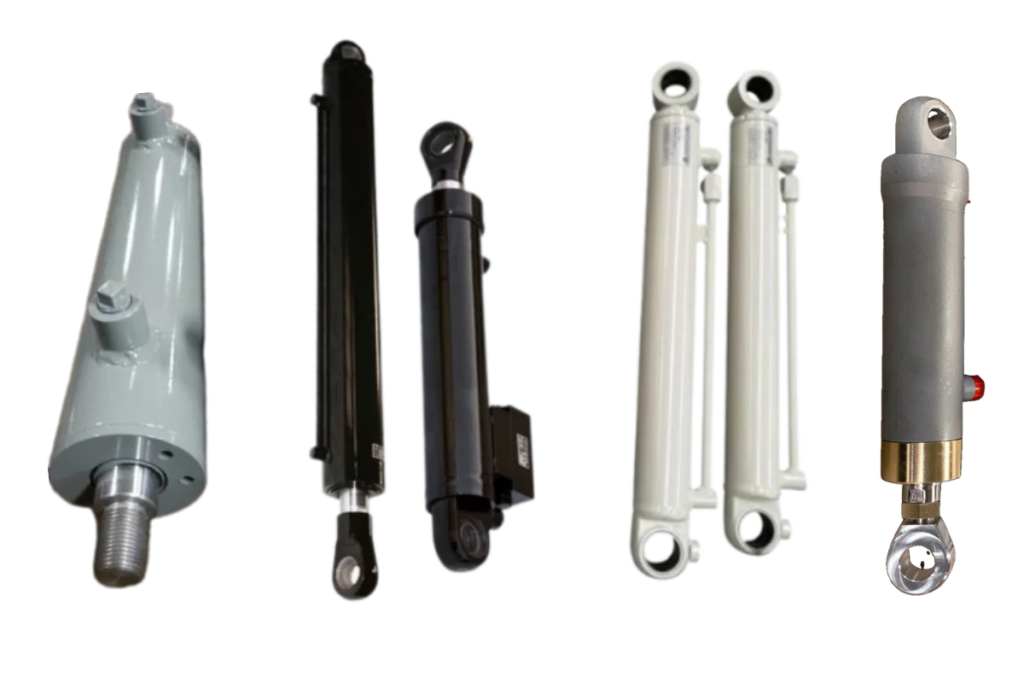

We specialize in designing and manufacturing for OEMs, single machine manufacturers, and in-house machine builders for specific applications, including vehicle-mounted solutions. This versatility allows us to produce a wide variety of cylinders, including both tie rod and welded types, as well as specialized designs.

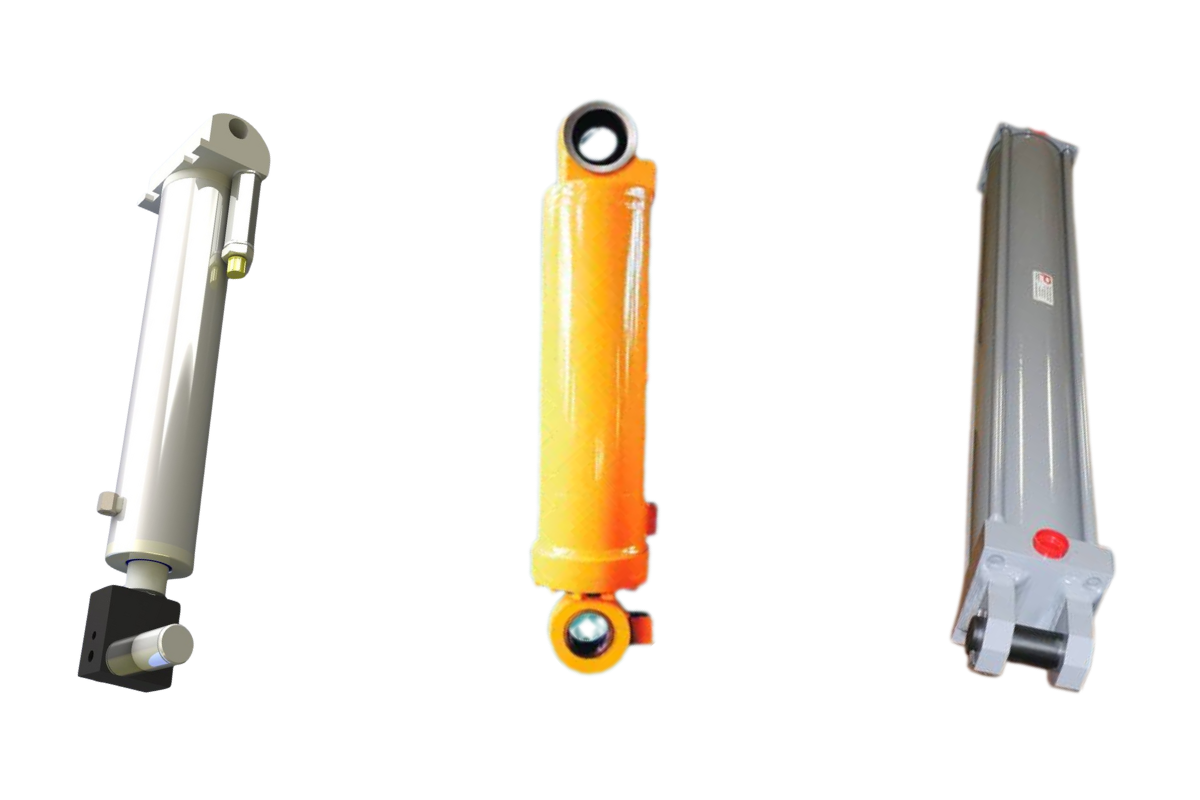

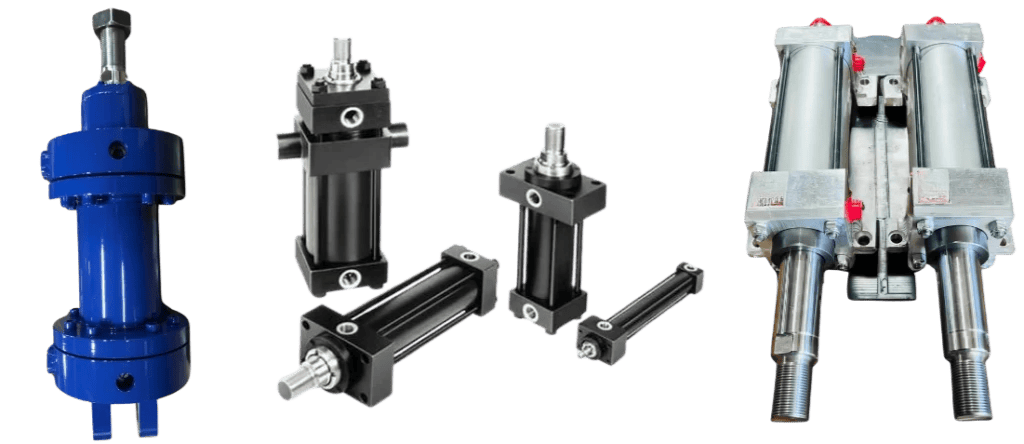

Double acting Cylinder means the cylinder has two ports. These are typically located at the bottom and the top of the cylinder. Fluid is pumped into the bottom port to extend the piston much like a regular single acting cylinder. But when the operator wants to retract the piston, fluid is pumped through the top port to push it back. This allows for more control of the system. The faster and predictable retraction of double-acting cylinders makes them the better choice for projects needing repeatable accuracy.

Hydraulic cylinders are used as linear actuators to apply unidirectional force and stroke in many Engineering applications. Hydraulic cylinders are used to create mechanical force in a linear motion. They are used to lift something, push something, press something, and many other types of work.

A single acting hydraulic cylinder, also known as a single acting hydraulic ram, operates in a single direction. It typically has a single port at the bottom of the cylinder where pressurised fluid is pumped into the system. As the fluid enters the system, it fills the cylinder and extends the piston inside.

To retract the piston, a single acting hydraulic cylinder must rely on an external force to expunge the fluid inside. This can be left to gravity if there is no immediate need to retract the piston, but a second piston can also be used to forcefully push the piston back into the cylinder. Springs can also be used if they are strong enough.

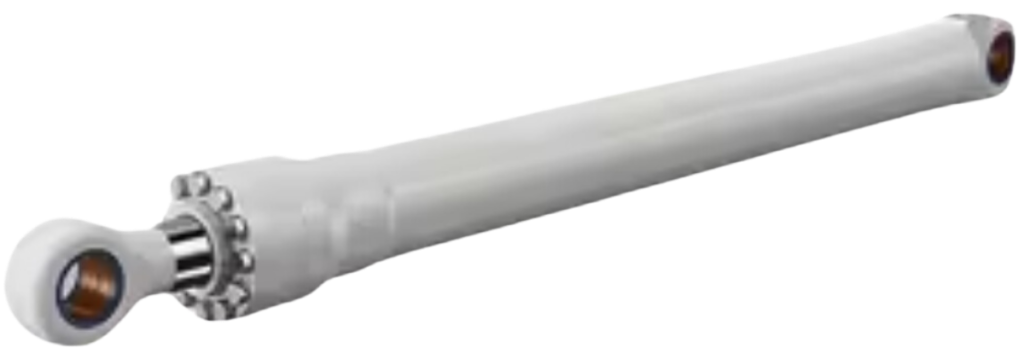

Parking Cylinder is mainly a Telescopic Single Acting Cylinder having different stroke depending on customers’ requirements. Hydraulic cylinders are commonly used in parking systems due to their reliability, efficiency, and ability to handle heavy loads with smooth, controlled motion. They are a key component for ensuring safe and effective operation in both indoor and outdoor car parking solutions.

| STROKE MM | MAX LOAD CAPACITY | MAX WORKING PRESSURE |

| 1650 | 2 TON / 4 TON / 6 TON | 240 BAR |

| 1750 | 2 TON / 4 TON / 6 TON | 240 BAR |

| 1850 | 2 TON / 4 TON / 6 TON | 240 BAR |

| 1950 | 2 TON / 4 TON / 6 TON | 240 BAR |

| 2050 | 2 TON / 4 TON / 6 TON | 240 BAR |

| 2100 | 2 TON / 4 TON / 6 TON | 240 BAR |

| 2150 | 2 TON / 4 TON / 6 TON | 240 BAR |

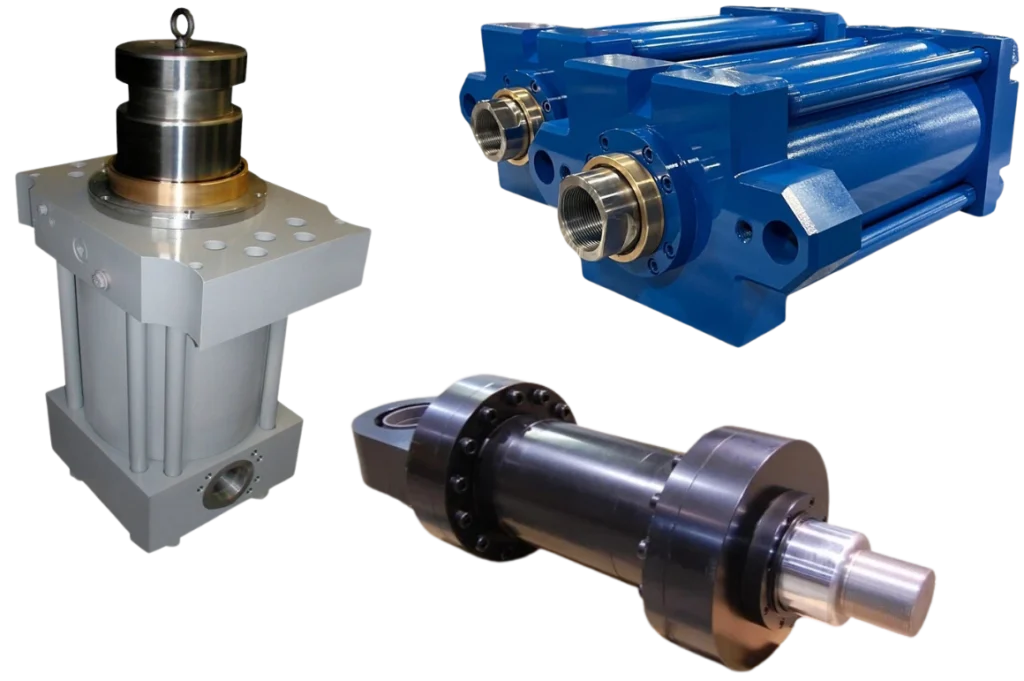

Ram type hydraulic cylinders are widely used in industrial applications that require high force, particularly for push and pull actions. These cylinders have a unique design where the piston rod cross-sectional area is larger than the cross-sectional area of the moving parts, allowing them to deliver substantial force efficiently.

Technical Specifications:

Technical Specifications:

Technical Specifications:

Hydraulic cylinders are used as linear actuators to apply unidirectional force and stroke in many Engineering applications. Hydraulic cylinders are used to create mechanical force in a linear motion. They are used to lift something, push something, press something, and many other types of work.

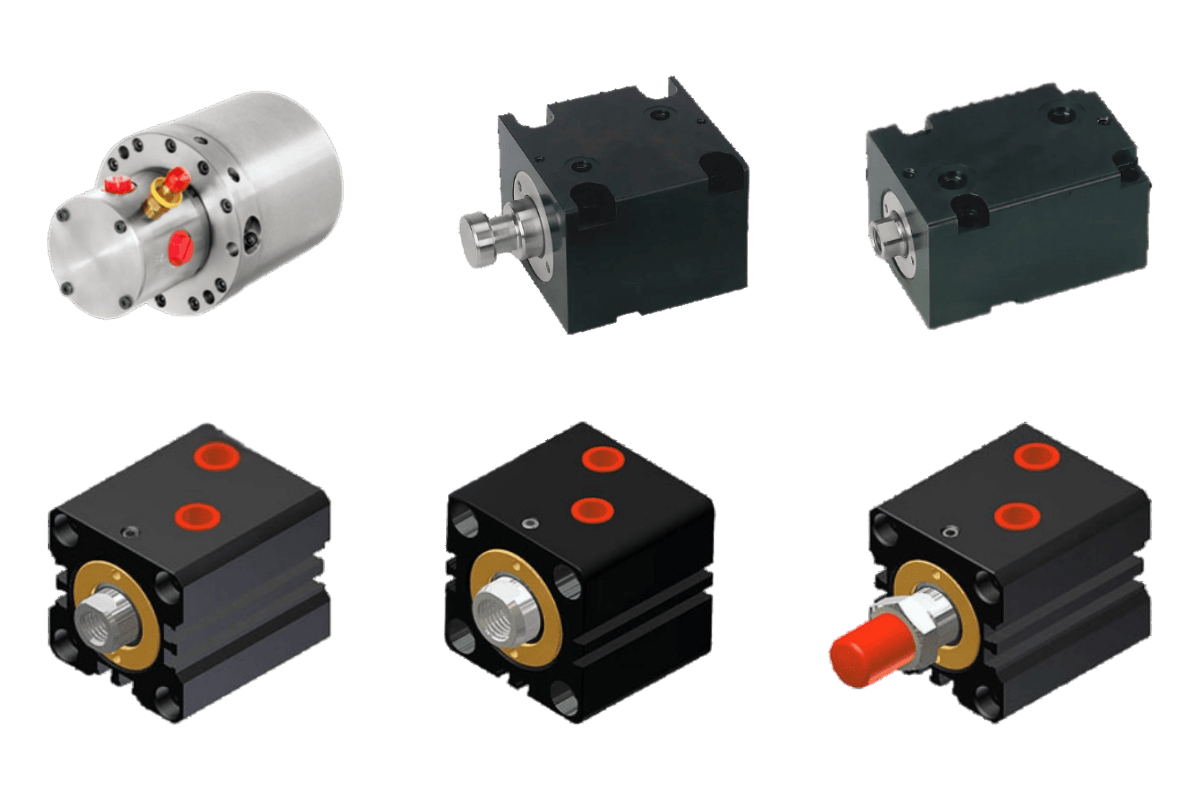

compact hydraulic cylinders are greatly valuable mechanical gadgets that are utilized to lift overwhelming loads. Utilizing hydrodynamics, these jacks can bear more noteworthy lift over bigger separations. hydraulic jacks are commonly utilized within the car, mechanical, and development industries.

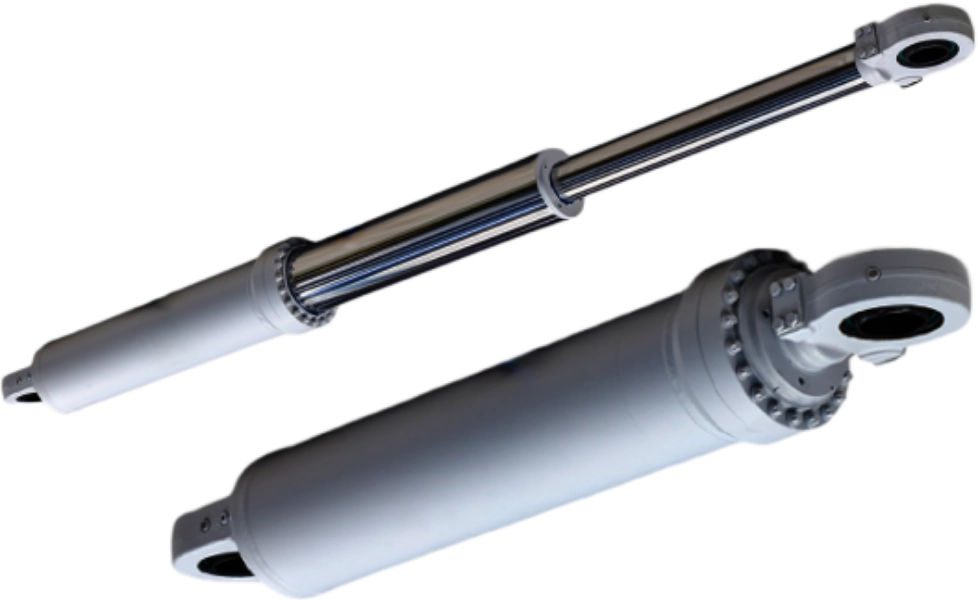

A type of hydraulic cylinder that consists of two or more cylinders working in sequence (one after another) to provide a combined force or motion. In a tandem cylinder, the pistons are arranged in such a way that each piston extends in sequence from the same hydraulic pressure, which allows for more control over the movement and increased force. These cylinders are commonly used in applications where extended stroke lengths or higher load capacities are required and many other types of work.

Hydraulic cylinders are used as linear actuators to apply unidirectional force and stroke in many Engineering applications. Hydraulic cylinders are used to create mechanical force in a linear motion. They are used to lift something, push something, press something, and many other types of work.

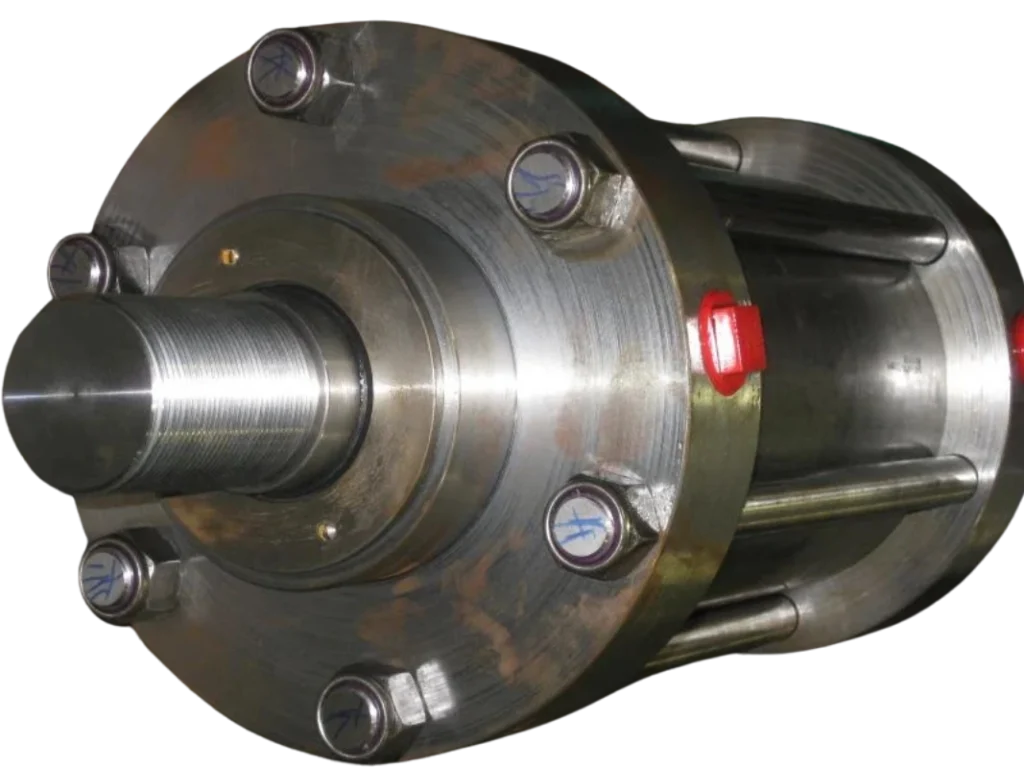

Tie-rod cylinders are most often used in industrial factory applications. They use high strength, threaded steel rods and nuts to hold square or rectangular end caps to each end of the cylinder barrel. Seals are placed between the barrel and end cap to prevent leakage. Smaller cylinders usually use 4 tie-rods, but larger bore cylinders can use up to 20. Tie-rod cylinders are useful because they are not as complex in design as welded-body cylinders and can be completely disassembled for service and repair.

Magnetic Cylinder is a specialized type of hydraulic or pneumatic cylinder that incorporates magnetic sensors (such as reed switches or magnetostrictive sensors) to detect the position of the piston within the cylinder. The magnet(s) are embedded in the piston, and as the piston moves, the magnetic field interacts with the external sensors, allowing for accurate position feedback.

Magnetic cylinders are widely used in automation and industrial systems where position sensing, high precision, and reliability are required. Specifications of Magnetic Cylinders

Hydraulic cylinders are used as linear actuators to apply unidirectional force and stroke in many Engineering applications. Hydraulic cylinders are used to create mechanical force in a linear motion. They are used to lift something, push something, press something, and many other types of work.

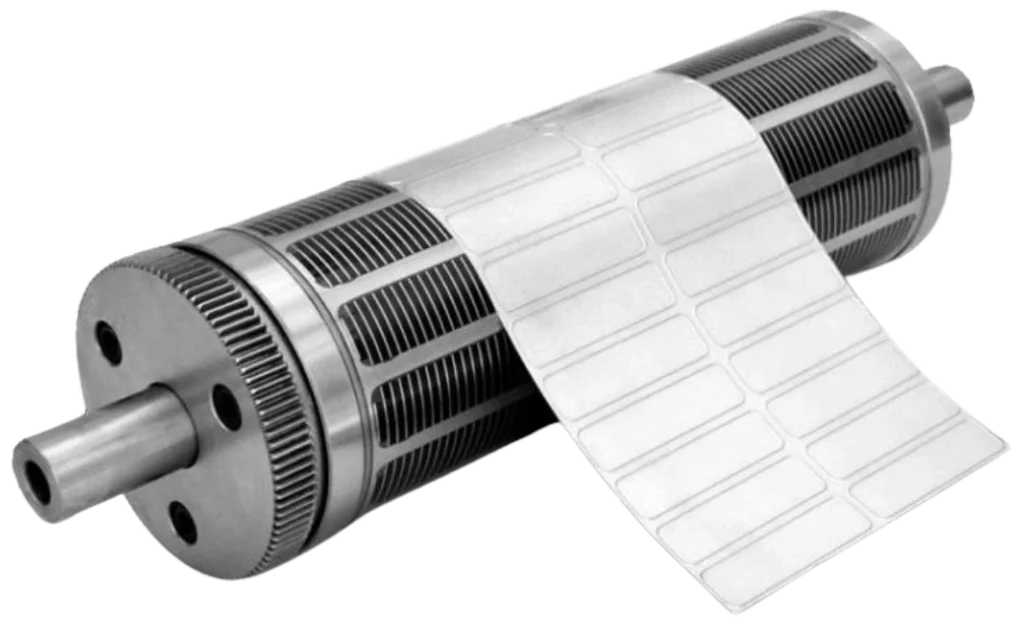

In every system, the most important component is a hydraulic cylinder and it will convert hydraulic energy to mechanical energy. The power of pressurized hydraulic fluid will push/pull the piston rod attached to the cylinder for applying the required compressive force on the work piece.

A hydraulic press is a mechanical device that uses the static pressure of a liquid, as defined by Pascal ‘s principle, to shape, deform, and configure various types of metals, plastics, rubber, and wood. The mechanism of a hydraulic press consists of a mainframe, power system, and controls.

The Cushion Type Hydraulic Cylinder is engineered to provide a controlled cushioning effect, minimizing shock and impact during operation. Designed for durability, it enhances performance in various applications, such as construction and material handling.

This cylinder features a robust construction that reduces wear and extends lifespan, ensuring reliable operation. Available in multiple sizes and specifications, it can be tailored to meet specific needs. Optimize your hydraulic systems with the efficiency and reliability of the Cushion Type Hydraulic Cylinder.