At Deep Hydropneumatic & Lubrication, we specialize in the repair, reconditioning, and manufacturing of all types of hydraulic cylinders. Initially focused on hydraulic cylinder repairs, we have expanded our services to include the production of new, custom-designed cylinders, tailored to meet specific applications. With our extensive industry knowledge and experience, we continuously refine our capabilities to deliver the most effective solutions for all your hydraulic needs.

Our hydraulic cylinder repair services cater to critical industries and applications, including:

A key aspect of our repair services is honing, a precision process in which abrasive stones smooth and finish the cylinder surface. This restores the integrity of the cylinder, extends its lifespan, and ensures optimal performance and reliability. Honing is crucial in preventing unnecessary downtime and maintaining your hydraulic systems at peak efficiency.

We understand the importance of timely maintenance. By proactively assessing the condition and lifespan of your hydraulic cylinders, we monitor wear over time and create a tailored maintenance schedule. This approach minimizes downtime by identifying and addressing potential issues before they lead to equipment failure.

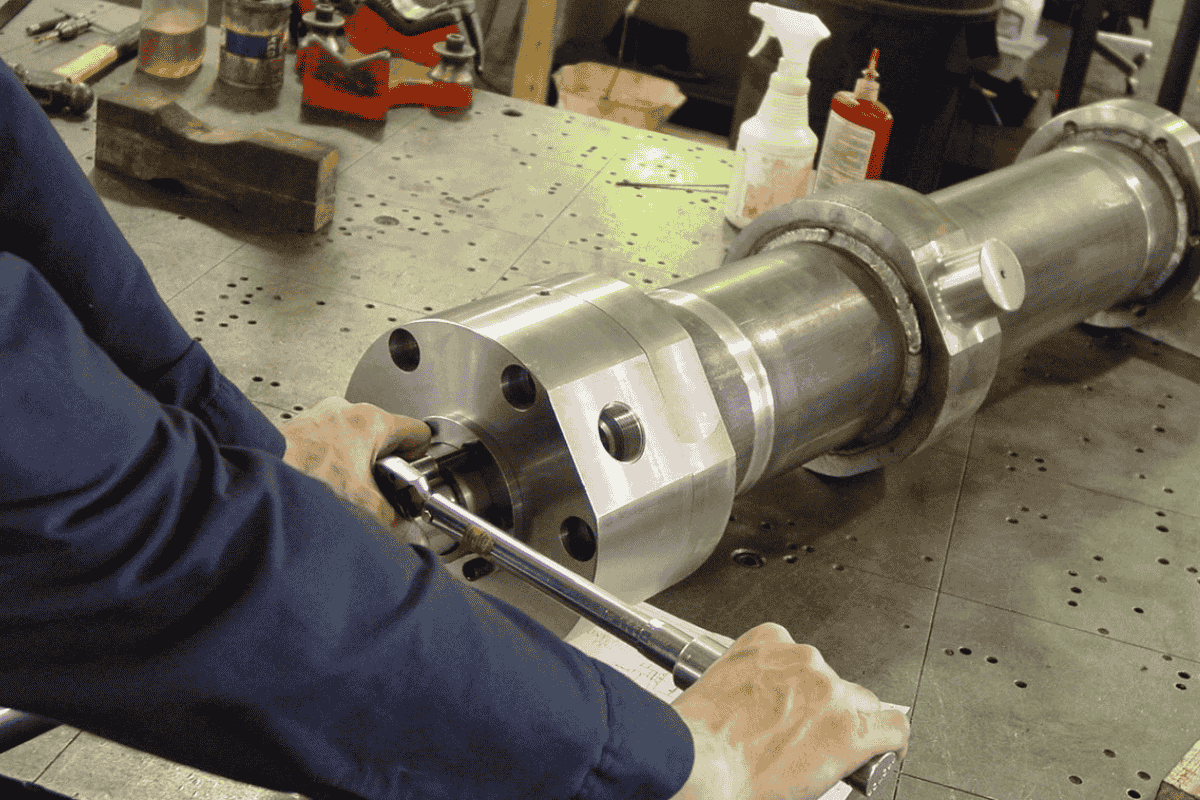

At Deep Hydropneumatic & Lubrication, we are experts in repairing hydraulic cylinders, jacks, oil pumping units, actuators, dampeners, and other hydraulic equipment. Repairing hydraulic components, rather than replacing them, is often a more cost-effective solution, especially when handled by our team of experts. In many cases, a repaired cylinder will perform as well as a brand-new model.

When you choose us for hydraulic cylinder repairs, you are guaranteed the highest quality of service through:

We conduct thorough assessments to identify the root cause of failure and determine the most effective repair solution.

Our team evaluates which parts can be salvaged and determines the most economical approach to ensure you get the best value.

Our repair process involves specialized departments working collaboratively to ensure your hydraulic cylinder repair meets the highest standards of quality and performance.

Our expert design team works to enhance the performance and longevity of your hydraulic cylinders, continuously seeking ways to improve machinery efficiency.

We maintain a large inventory of seals, chrome-plated rods, cylinder barrels, pistons, glands, and other essential components, ensuring prompt repairs. If a part is not in stock, we can usually source it within 24-36 hours.

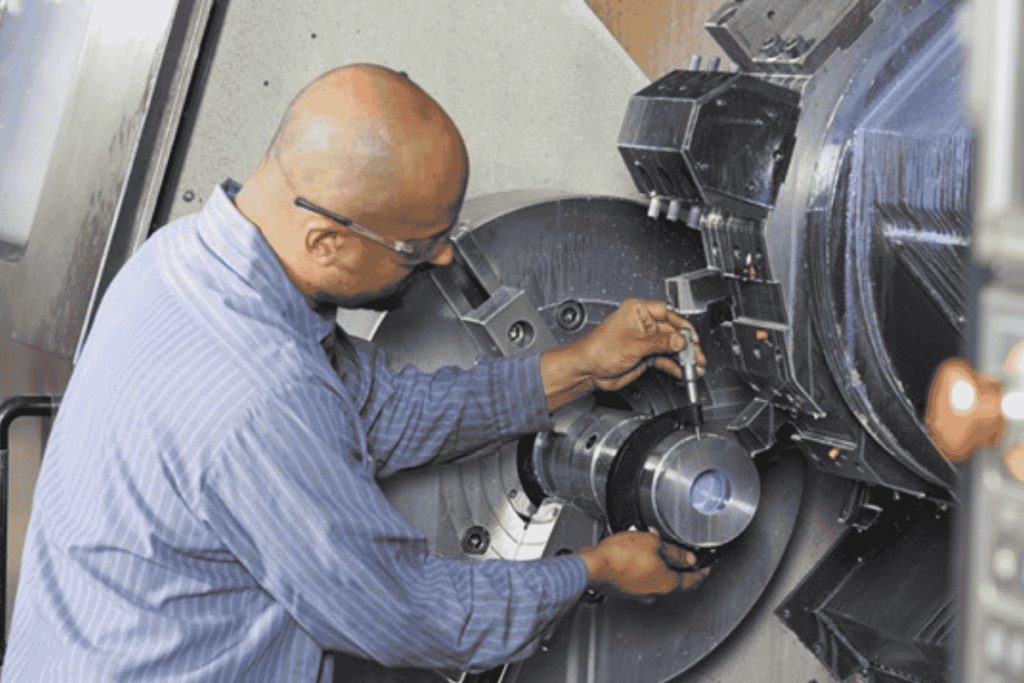

Equipped with advanced technology and conventional equipment, our machine shop manufactures precision components tailored to your hydraulic cylinder requirements.

Our clean and well-equipped fitting shop ensures that all components are carefully assembled to the highest quality standards.

After assembly, each hydraulic cylinder undergoes rigorous testing and inspection to ensure it meets ISO 9001 quality standards, guaranteeing optimal performance and safety.

To protect your hydraulic cylinders from future corrosion, we apply protective paint coatings. We offer a variety of coatings, including offshore and subsea-grade options, customized to meet your specific requirements.

Comprehensive Solutions: At Deep Hydropneumatic & Lubrication, we specialize in repairing and rebuilding hydraulic presses, cylinders, and related components. We offer large-scale refurbishment services to manufacturing businesses across the U.S., with a focus on minimizing downtime through efficient and cost-effective repairs and quick turnaround times.

Hydraulic cylinders are key components of hydraulic systems, converting hydraulic energy (fluid pressure) into mechanical force and motion. These cylinders are widely used in various industries, including construction, manufacturing, transportation, and even aerospace, to provide linear motion and perform a wide range of tasks such as lifting, pushing, pulling, or pressing.

A hydraulic cylinder repair is a process that involves repairing or replacing damaged or faulty components in a hydraulic cylinder, which is a mechanical actuator used to provide linear force and motion through the use of pressurized hydraulic fluid.

Hydraulic cylinder repair is important because it helps to maintain the performance and functionality of hydraulic equipment. Regular repairs can prevent costly breakdowns and ensure safe and efficient operation of machinery.

Some signs that a hydraulic cylinder may need repair include leaking fluid, unusual noises, slow or erratic movement, and visible damage to the cylinder or its components.

While it is possible to perform some basic repairs on a hydraulic cylinder, it is not recommended for individuals without proper training and experience. Hydraulic systems can be dangerous and complex, and it is best to leave repairs to trained professionals.

The time it takes to repair a hydraulic cylinder can vary depending on the extent of the damage and the availability of replacement parts. In general, minor repairs can be completed in a few hours, while more extensive repairs may take several days.

Yes, regular maintenance is crucial for preventing frequent hydraulic cylinder repairs. This includes regularly checking for leaks, keeping the cylinder clean, and following manufacturer’s guidelines for lubrication and fluid changes. It is also important to address any issues or abnormalities as soon as they are noticed.

Hydraulic cylinder damage can result from various sources, such as hydraulic fluid contamination, deterioration of seals and components, insufficient maintenance, and improper operational testing procedures. These factors can significantly affect the performance and efficiency of hydraulic systems.

A comprehensive understanding of these common causes is crucial for effective troubleshooting and the implementation of preventative maintenance strategies, thereby extending the lifespan of hydraulic cylinders.