We provide a wide range of pneumatic valves designed to control and direct compressed air for various industrial applications. Our focus is on delivering high-quality, reliable products at competitive prices that meet or exceed our customers’ expectations.

Pneumatic directional control valves manage the flow and direction of compressed air in systems, allowing precise control of actuators and machinery. Available in various configurations, these valves ensure reliable performance and enhance the efficiency of industrial operations.

The solenoid-operated directional control valve (DCV) is an essential component in pneumatic systems, enabling precise control over airflow and pressure. This device utilizes an electromagnetic solenoid to actuate the valve, allowing for seamless switching between different flow paths. Its robust design ensures reliability and efficiency, making it ideal for various applications where accurate fluid management is crucial.

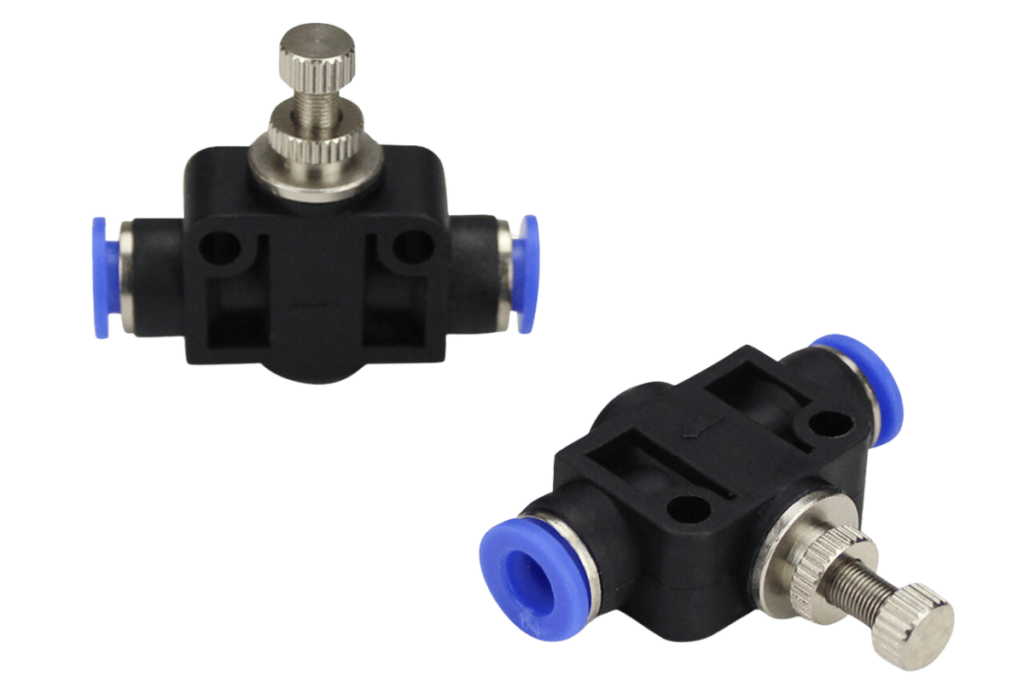

Inline valves are key elements in pneumatic systems that manage air or gas flow efficiently. Their compact design ensures smooth operation and precise control of pressure and airflow direction. Ideal for applications requiring reliability in tight spaces, these valves offer easy installation and consistent performance.

These valves are essential components in pneumatic systems, designed to prevent backflow while allowing fluid to flow in one direction. They utilize a pilot mechanism that controls the opening and closing of the valve, ensuring efficient operation under varying pressure conditions. With their reliable performance and quick response time, these valves are ideal for applications requiring precise flow control and safety in fluid transport.

Inline slide valves are essential components in pneumatic systems, designed to control the flow of air with precision. These valves feature a straightforward sliding mechanism that allows for quick and easy adjustments, ensuring optimal performance and efficiency in various applications. Their robust construction enhances durability, making them ideal for use in demanding environments where reliable operation is crucial.

G1/4, 3/8, 1/2, 3/4, 1, 1¼, 1½, 2

We offer our clients a wide range of precision engineered FRLs (Filters, Regulators and Lubricators). These are manufactured from finest grade basic material to ensure optimum quality and durability. Clients can avail different types of Filters, Regulators and Lubricators; including Air Filters, Air Filter Regulators, Precision Air Pressure Regulators, Lubricators and our patented FRL 500, amongst many others.

A needle valve is a type of valve having a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

• Pressure range up to 500 Bar.

• MOU- Carbon Steel, Stainless steel (304/316), Brass.

• For all general application such as Oil, Water. Gas, Steam, and other wide range of fluids.

• Size 1/8″ BSP to 1 1/2″ BSP.

Inline flow control calves are used to control and adjust a flow of hydraulic fluid. These valves precisely control flow of the fluid in the system.

• Pressure range up to 500 Bar

• MOU- Carbon Steel

• Size 1/4″ BSP to 2″ BSP.

Gauge Isolator valves isolate gages from damage and inaccurate readings caused by line pressure surges and hydraulic hammer.

These seat type valves allow free flow from port A to port B and give leak-proof closure in opposite direction. Various sizes are available as per customer needs.

• Pressure range up to 350 Bar Flow up to 360 LPM

• Choice of Cracking pressure 5 / 50 PSI.

• MOU- Carbon Steel.

• Size 1/4” BSP to 2” BSP.

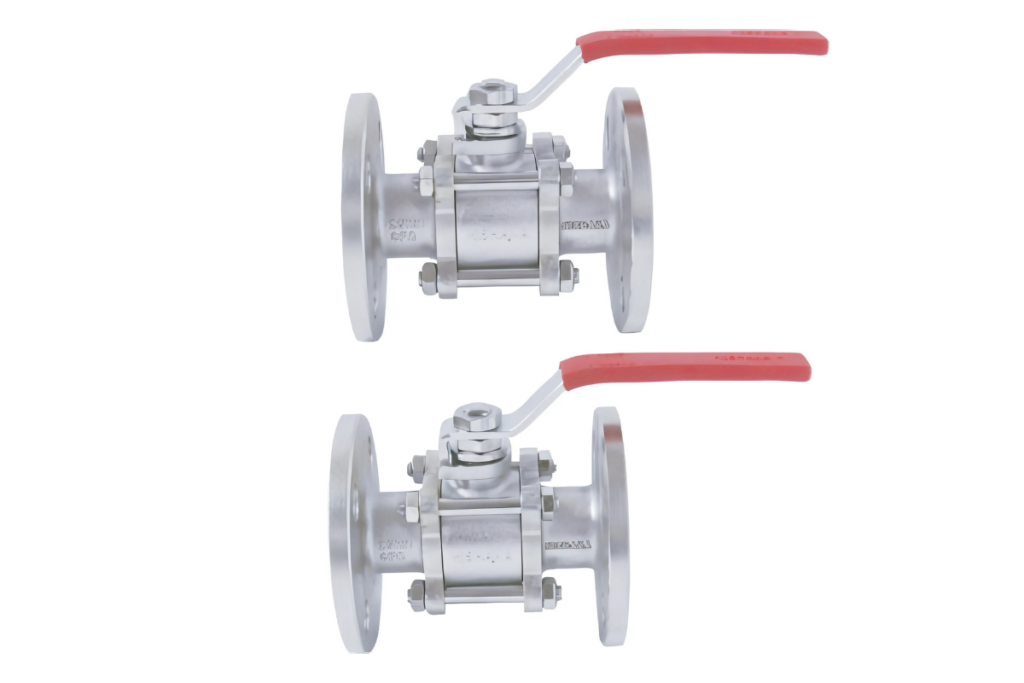

These valves are widely acclaimed owing to their reliability, design flexibility, excellent performance, longer functional life and dimensional accuracy.