As a leading hydraulic hose manufacturer in India, DHL has over 15 years of experience in producing high-quality hydraulic hoses and fittings. Our factory specializes in crafting custom hydraulic pipes and industrial hoses designed to withstand harsh conditions, including high temperatures, high pressures, and corrosive environments.

Our products implement SAE and DIN EN standards, widely used in construction machinery, the coal chemical industry, agricultural machinery, metallurgy, mining, Petroleum, ships, marine and heavy industrial equipment, and other fields.

The hydraulic hose is a critical industrial component that transfers high-pressure fluids in hydraulic systems. They are usually made of multiple layers of material to provide adequate strength and durability.

Construction : Hydraulic hose usually consists of three layers: inner tube, reinforcement, and cover protection.

Pressure Rating : Hydraulic hoses are classified according to their maximum working pressure.

Dimensions : Dimensions for hydraulic hoses include ID, OD, and length.

Connectors : The types of connectors include threaded connections, flange connections, and quick connectors.

Temperature Range : Hydraulic hoses need to operate within a specific temperature range.

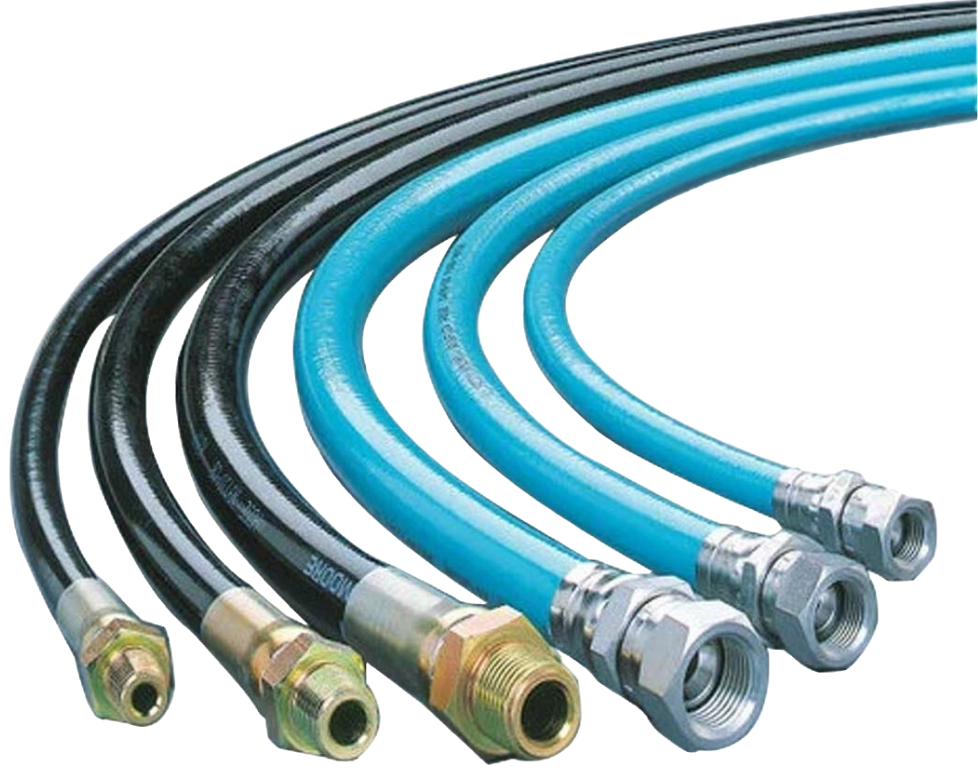

Our hydraulic hoses including:

braided hydraulic hose, spiraled hydraulic hose & thermoplastic hydraulic hose.

Industrial hoses are rubber or plastic tubes of varying sizes and lengths that are used to transfer liquids, gases, and other materials from one place to another. They are used in a wide range of industries and applications, including agriculture, construction, manufacturing, and mining. Industrial hoses are designed to withstand extreme temperatures, pressures, and abrasive materials. They are also designed to be flexible and durable and can be used in various applications.

Air Hose, Water Hose, Fuel Hose, Welding Hose, Pressure Washer Hose, Steam Hose, Suction and Discharge Hose, Rubber Oil Hose, Abrasive Sandblasting Hose, Automotive Hose, LPG Gas Hose, Multipurpose Hose, Welding hose

When it comes to low pressure hydraulic rubber hose, we alway focus the words “low pressure”, but in hydraulic hose industry, there is no definite concept to tell what is low pressure hydraulic hose. Here we consider the hydraulic hose with 10 mpa working pressure or even below as low pressure hydraulic hose based on our experience.

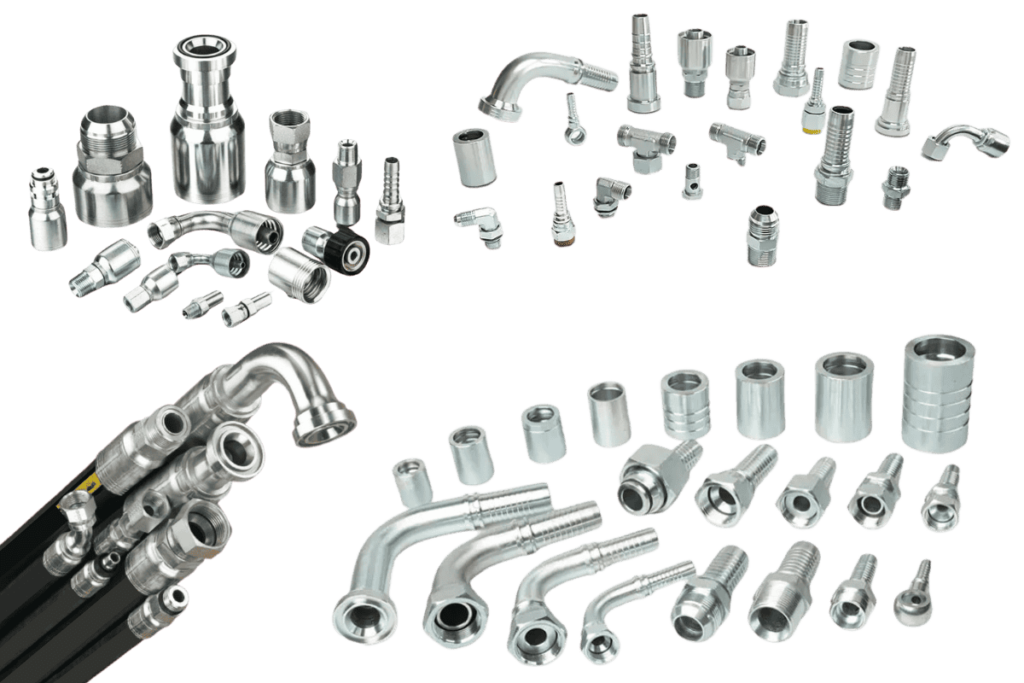

Hydraulic hose fitting is a component that connects a hydraulic hose to other parts of a hydraulic system. These fittings are typically crimped onto the end of a hydraulic hose to ensure a secure, leak-proof connection. Hydraulic fittings are designed to accommodate specific thread types or flanges, which allows them to connect with other hydraulic components such as valves, pumps, cylinders, and actuators. The main type includes Metric, BSP, JIC, NPT, SAE, SAE, NPSM, JIS.

Automotive hoses are flexible tubes that convey fluids and gases in automotive systems. They are used in various applications, such as cooling systems, fuel delivery, and power steering systems. Automotive hoses are made from multiple materials, including rubber, plastic, and metal. They are designed to withstand extreme temperatures, pressure, and vibration. Automotive hoses are available in various sizes and shapes to fit the needs of different vehicles.

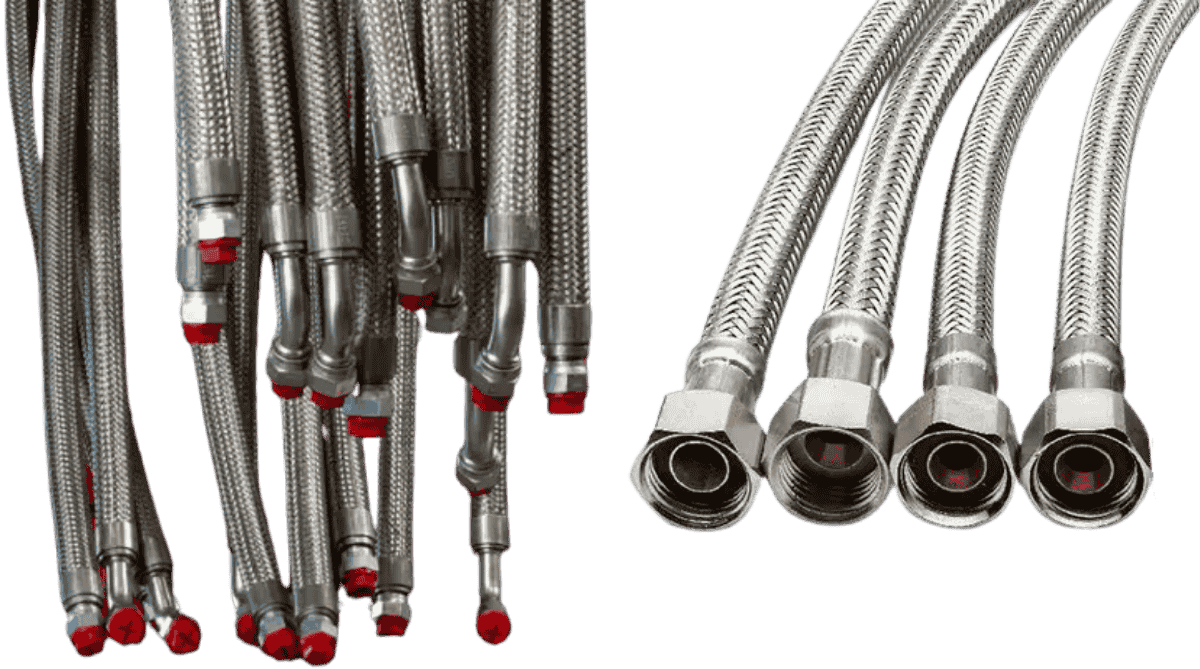

Thermoplastic hose is a kind of hose made of thermoplastic that can be heated up to 120 degrees and is powered by water pressure or pneumatic. It has the characteristics of lightweight, pressure resistance and corrosion resistance. Our SAE thermoplastic hoses have two layers of braided synthetic fibers and a polyurethane outer coating, making them abrasion resistant. Rated up to 212 F(100°C), the thermoplastic hoses are used in many hydraulic applications. Thermoplastic hydraulic hoses offer excellent abrasion resistance and flexibility, and are resistant to a wide range of chemicals.

Thermoplastic hoses are used to convey various fluid media, such as water and petroleum inside. Used in chemical machinery, printing machinery, plastic machinery, electronic manufacturing equipment, food packaging industry, medical equipment, and auto parts.

Thermoplastic hoses are used in chemical machinery, printing machinery, plastic machinery, electronic manufacturing equipment, food packaging industry, medical equipment, and auto parts.

DHL has a full range of braided hydraulic hoses to meet the requirements of all low, medium and high pressure hydraulic applications. Whether you need high-performance hoses for critical systems or standard hoses for others, DHL can supply.

Wire braid hydraulic hoses can be divided into many types according to the layer number. Here we will introduce two kinds of wire braid hydraulic hoses that are widely used in the markets. They are namely single wire braid hose and double wire braid hose.

DHL braided hydraulic hoses are fundamental fluid conveyance solutions for various equipment and applications with wide operating pressure ranges, optimal levels of abrasion resistance, long-lasting durability and high-performance transfer capabilities.

DHL hydraulic steel wire braided hoses are designed with a safety factor of 4:1 relating minimum burst pressure and recommended working pressure.

Hydraulic hoses are designed for petroleum base hydraulic fluids applications with a temperature range of –40˚C (-40˚F) to +100˚C (+212˚F). Special rubber compounds and other lining materials allow to exceed these limits.

Hydraulic hoses may also be used for water base hydraulic fluids if the working temperature does not exceed +70˚C (+158˚F).

For conveyance of Hot Air working temperature should be reduced to a maximum of +60˚C (+140˚F)

Hose protectors are essential components that safeguard hydraulic, pneumatic, and industrial hoses from damage, abrasion, and environmental factors. They help extend the life of the hose and ensure safe and reliable operation. Hose protectors come in various types and materials to meet specific application needs.

Material: PP (Polypropylene)

Application: Such hose sleeve is economical and convenient to protect the hydraulic and pneumatic hose, cable, wire and rope from premature wear. It can also extend the service life if them. Spiral wrap tubing can bear the extreme climate and work conditions. Spiral Guard Wrap protects against abrasion, cuts, crushing, UV and various hazards. Spiral Guard Wrap’s open spiral design makes it easy to install in the field, without the need to disconnect lines.

TEMPERATURE: -50°C to +80°C

Hose assemblies and fittings are critical for fluid transfer across a wide range of industries. They are designed to securely connect hydraulic and fluid transfer hoses to other system components, ensuring a leak-free and efficient operation. Available in various sizes, materials, and configurations, these fittings can handle different pressure levels and temperature requirements.

Hydraulic fittings are components used to connect hoses, pipes, and tubes in hydraulic systems. They are often used to join two sections of a hydraulic hose together or to connect a hose to a port or adapter. Hydraulic fittings come in various shapes and sizes and are made from multiple materials, including brass, steel, stainless steel, and plastic. They are designed to withstand high pressures and temperatures and are often used in industrial and automotive applications. Hydraulic hose fittings include JIC, SAE, NPT, and BSP.

Our standard hydraulic fittings are as follows:

Ferrule, Metric Fittings, British BSP Fittings, American SAE, ORFS, NPSM, JIC, NPT Fitting, SAE Flange, JIS Fittings, Staplelok Fitting, Banjo, Double Connection, Reusable Hose Fitting

Advantages of Using Hydraulic Fittings: