We manufacture hydraulic presses, press lines and die handling equipment customized for your specific application. Our goal is to supply the highest quality equipment at competitive prices that will meet or exceed our customer’s expectations.

C-frame Type Hydraulic Press is stable and reliable, high-precision, easy to use, small footprint, widely used and easy to maintain.

We can provide 5-200 tons’ standard hydraulic presses, and can also be customized according to customer requirements.

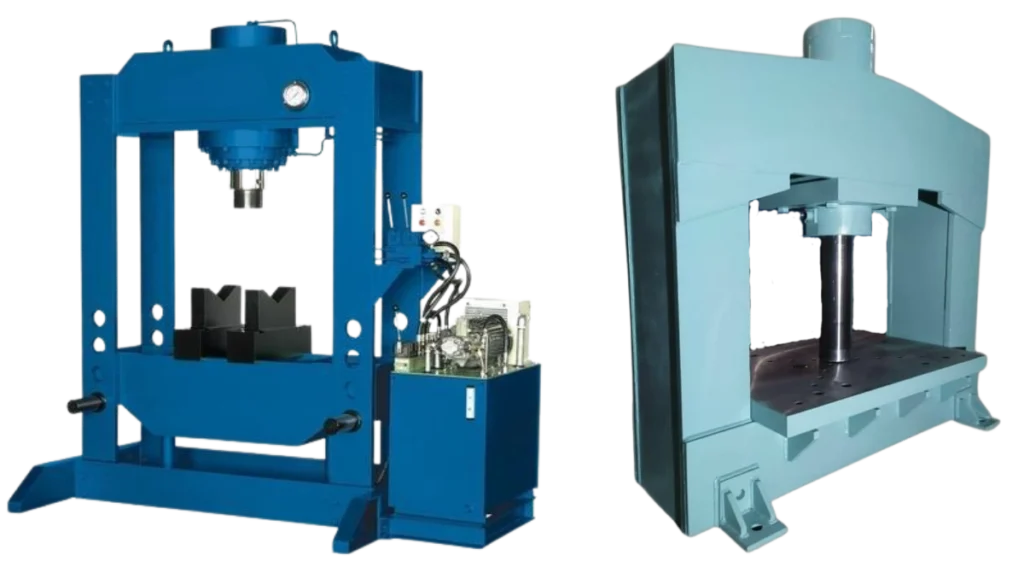

The H-frame press is a smaller type of press, which is more convenient to carry and use. It adopts a double-column structure, which is simple, economical, and practical. The H-frame hydraulic press machine is equipped with a hand pump and is generally used for small-batch production.

Our products range in capacity from 10 tons to 200 tons and are widely used in forging, riveting, forming, blanking, stamping, deep drawing, and metal forming operations. It is suitable for the pressing operation of large, medium and small enterprises, factories, industrial mines, and auto repair shops.

Two/four-column type double action hydraulic press is stable, reliable and has high precision. The four-column structure provides a flexible and open space for automated production, and can provide a full set of automation solutions according to customer needs.

Provide users with standard models of 50-1000 tons, and can also provide customers with customized models.

Deep Hydropneumatic & Lubrication Works offers Gravity Die Casting Machines designed to meet the needs of complex automobile components. These machines are engineered for efficiency, flexibility, and full automation, ensuring they perform reliably over time. We customize each machine based on specific customer requirements, delivering optimal solutions tailored to your production environment.

Hydraulic die spotting presses are crucial in the die and mold manufacturing process, offering significant improvements in accuracy, productivity, safety, and ergonomics. These presses are designed for precise and repeatable die spotting, simplifying mold attachment and removal. Below are the key features and advantages of hydraulic die spotting presses, highlighting their applications in various industries: