We design and manufacture pneumatic cylinders, actuators, and custom air-powered solutions tailored to your specific applications. Our commitment is to deliver high-performance products at competitive prices that consistently meet or exceed our customers’ expectations.

Custom pneumatic cylinders are tailored for applications requiring unique dimensions, specific mounting styles, or special features that aren’t achievable with standard models. These cylinders are built to handle unique operational needs—whether that involves specific pressure levels, environmental conditions, or space constraints. Designed in close collaboration with users, they can include features such as enhanced seal durability, unique piston configurations, or non-standard rod lengths to ensure efficient and dependable performance in challenging settings

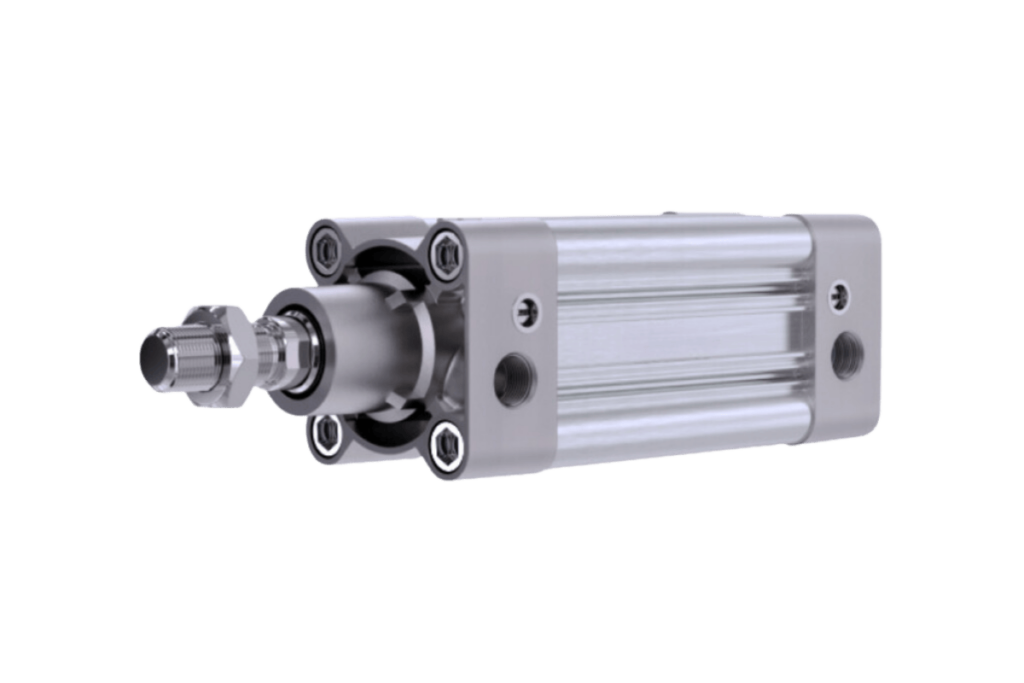

Confirm to ISO 6431 and ISO 15552 standards.

• Bore Diameter 32mm to 200mm

• Stroke as per customer’s requirement.

• Adjustable cushioning at both the ends.

• Magnetic and non magnetic version

• Optional High Temperature (Viton seals) upto 150 degree available.

• Optional SS piston rod with SS nut available.

• Wide Variety of Mountings available.

• Double acting Stroke Adjustment Air Cylinder

• Ask us for technical data sheet.

Confirm to ISO 15552 VDMA 24562 standards.

• Aluminum profile (square) cylinder barrel.

• Bore Diameter 32mm to 100mm

• Stroke as per customer’s requirement.

• Adjustable cushioning at both the ends.

• Magnetic and non magnetic version

• Optional High Temperature (Viton seals) upto 150 degree available.

• Optional SS piston rod with SS nut available.

• Wide Variety of Mountings available.

• Double acting Stroke Adjustment Air Cylinder

• Ask us for technical data sheet.

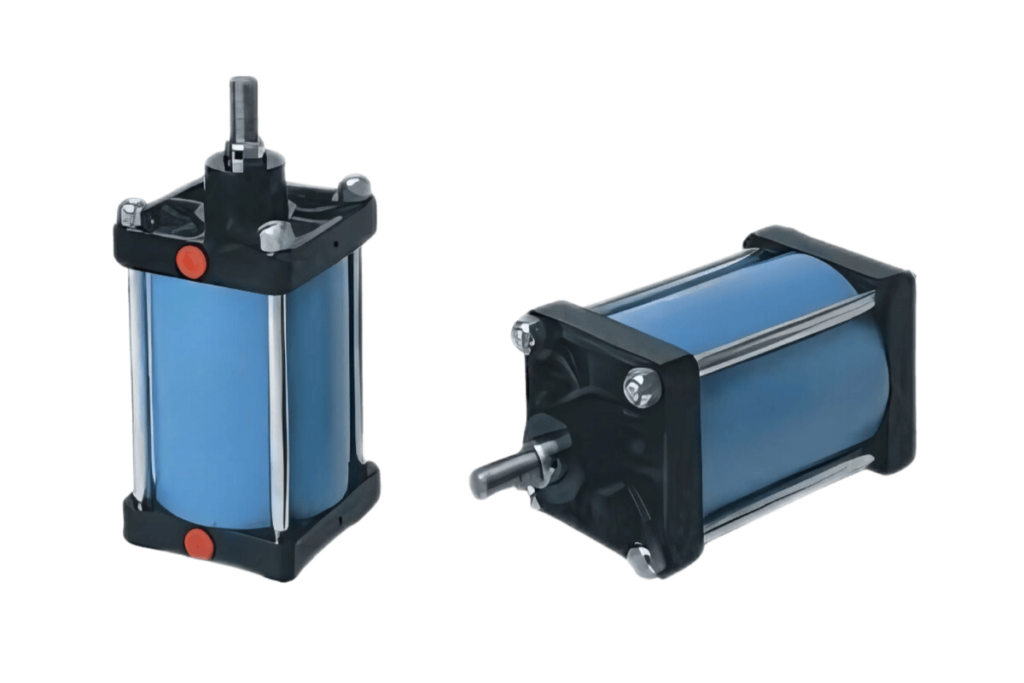

Double acting / Single acting Pneumatic Cylinders.

• Bore 100 mm to 350mm

• Stroke as per customer’s requirement.

• Adjustable cushioning at both end.

• Variety of Mountings.

• Accessories.

• Double end version available.

• Maximum Pressure – 10 kg/cm2

• MOU – End Cap: C.I, Barrel- Seamless Honed and hard chrome, Piston : EN8 hard chrome plated, Seals :Nitrile and Viton.

ISO 6432 Design.

• Bore 12mm to 25mm

• Stroke as per customer’s requirement.

• Internal Cushing ring. (Non Adjustable)

• Magnetic and non-magnetic version.

• Low friction, long life seal design.

• Maximum Pressure – 10 kg/cm2

• MOU – End Cap: Aluminum, Barrel- Stainless Steel, Piston : SS 410 roller burnished/ EN8 hard chrome plated, Seals : Polyurethane , Nitril and Viton.

• Refer to us for technical data sheet.

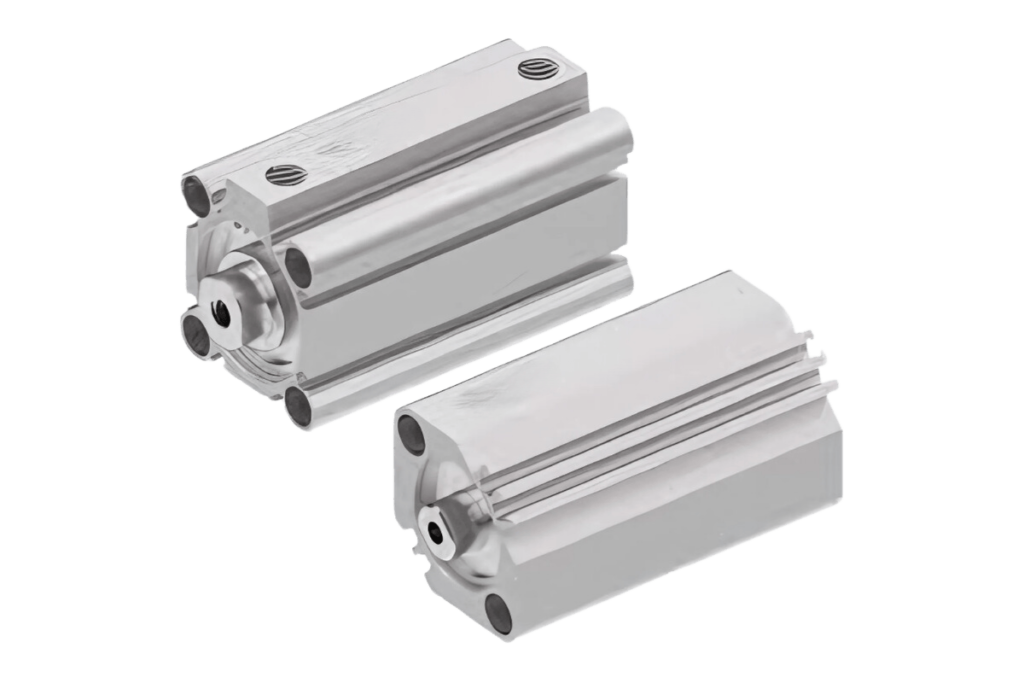

Confirm to ISO 21287 standards.

• Bore Diameter 12mm to 100mm

• Elastomer and

• Magnetic and non magnetic version

• Optional High Temperature (Viton seals) upto 150 degree available.

• Optional SS piston rod with SS nut available.

• Wide Variety of Mountings available.

• Double acting Stroke Adjustment Air Cylinder

• Refer to us for technical data sheet.

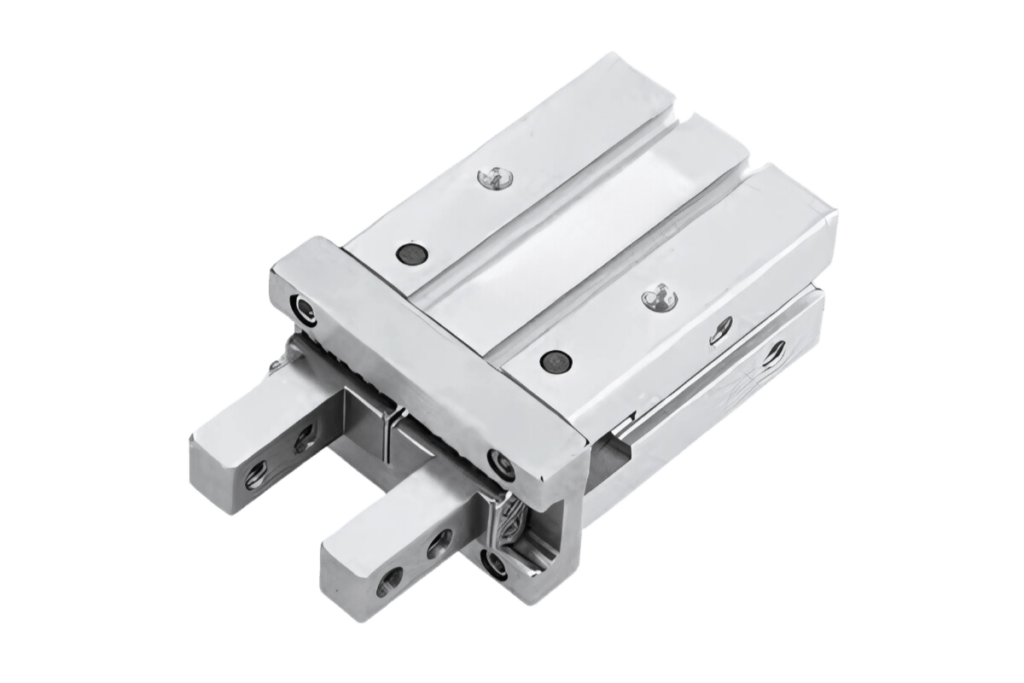

A pneumatic gripper is a versatile tool designed for handling, gripping, and transferring objects in automated processes. Powered by compressed air, it operates through a system of fingers or jaws that open and close with precise control, allowing it to securely hold objects of various shapes and sizes. Ideal for robotic systems and automated production lines, these grippers offer efficient, repeatable performance in tasks that require speed and accuracy, making them essential for industries like manufacturing, packaging, and material handling.